Automated IoT Platform

The automated IoT platform for greenhouses is a modern and sophisticated agricultural system that utilizes Internet of Things (IoT) technology to monitor and control various aspects of greenhouse operations. It combines sensors, control systems, and automation to create an optimized and efficient environment for plant growth.

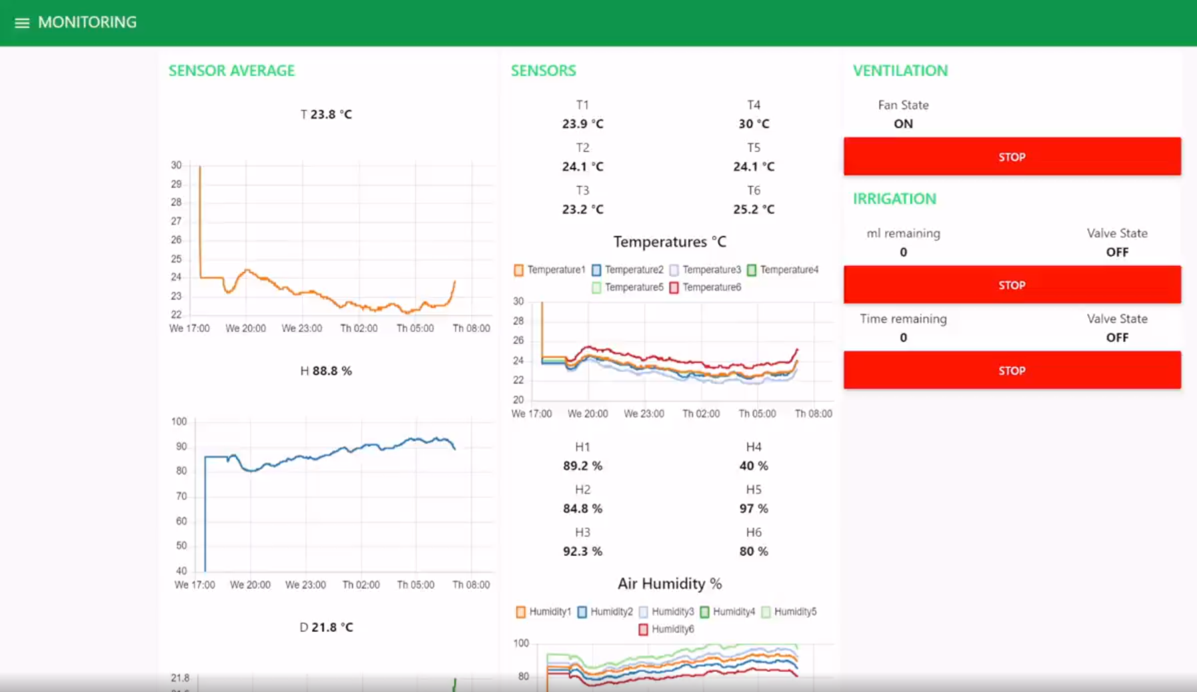

This system incorporates smart devices and connectivity to automate tasks and ensure optimal conditions for plants. It uses Wi-Fi sensors located inside greenhouses in physiologically relevant positions for the plants; where every sensor collects data on environmental factors such as temperature, humidity, and soil moisture. This data is then sent to a central control system, which automatically makes decisions and adjusts greenhouse components according with plant needs.

For example, if the temperature gets too high, the control system can activate fans or adjust ventilation to cool down the greenhouse. If the soil moisture is low, it can trigger an irrigation system to water the plants. The lighting system can be controlled to provide the right amount and spectrum of light for different plant stages. In cases where some variables reach dangerous limits, the system will send email and phone alerts. All control adjustments are made based on predefined parameters and references values set by the researchers through the developed remote web application.

This IoT platform tailored for greenhouses offers a comprehensive and interconnected system that brings automation, data collection, and control to the fingertips of scientist. By seamlessly integrating sensors, actuators, and smart devices, this platform enables real-time monitoring and management of crucial greenhouse parameters like irrigation and temperature. It integrates alarms to prevent crop disease/stress and reduce human errors.

This crucial deployment was made possible by the remarkable efforts of our Mechatronics Associates Harold Diaz, Duvan Pineda and Fabricio Soto, who designed and implemented all system in many greenhouses from its beginning to the complete, modern and user-friendly current version. Together with the collaborative integration of scientists’ supervision and support from Milan Urban, Roosevelt Escobar, Hector Buendia, Bodo Raatz, Steve Beebe and Joe Tohme.

In what context is this tool useful?

The automated IoT platform is useful in a wide range of contexts, including commercial farming, urban agriculture, research, sustainable farming practices, and educational purposes. It revolutionizes traditional greenhouse operations by combining advanced technologies to optimize plant growth, improve efficiency, and promote environmentally-friendly agricultural practices.

The system offers an ideal setting for conducting research and development activities in plant physiology, crop breeding, cultivation optimization, stress studies, disease and pest management, and data analysis. These advanced systems provide the necessary control, precision, and data collection capabilities required for scientific investigations, ultimately contributing to the advancement of agricultural knowledge and practices.

Expected results

It is important to note that the specific results achieved can vary depending on factors such as crop type, greenhouse design, technology implementation, and grower expertise. However, overall, the automated IoT platform for greenhouses has demonstrated their potential to enhance crop yields, resource efficiency, crop quality, and disease management, contributing to more sustainable and productive agricultural practices.

At the Alliance Palmira's campus, researchers have deployed this technology in more than 30 spaces including glass houses, mesh houses, in-vitro rooms, and tunnels for plant incrementation in crops such as beans, cassava, forages, and rice. Basically, this is a system to monitor and control environmental variables in the greenhouses (heating/cooling) at Palmira's campus.

Contact people

Milan Urban – [email protected] (Principal Scientist).

Harold Diaz – [email protected] (Main Developer).

Fabricio Soto – [email protected] (Technical Support).