Blog Improving food and nutrition security from reducing postharvest losses

A study in sweet potato value chain in Kenya revealed key strategies to reduce postharvest losses to improve food and nutrition security.

How many times have you thought about the processes the food you buy or that is on your plate has gone through to arrive healthy, nutritious and good looking? Have you ever imagined that what is waste, damage or “ugly” to you, could still feed someone? Something similar is what our scientists working in agricultural value chains have been asking themselves. There is a whole "universe" from when the food leaves the field until it reaches the final consumer, where multiple factors can degrade food safety, quantity and quality. That degradation is known as postharvest loss, which represents a major loss in value within the supply chain, and should be taken into account to reduce its effects as little as possible on the final product received by consumers.

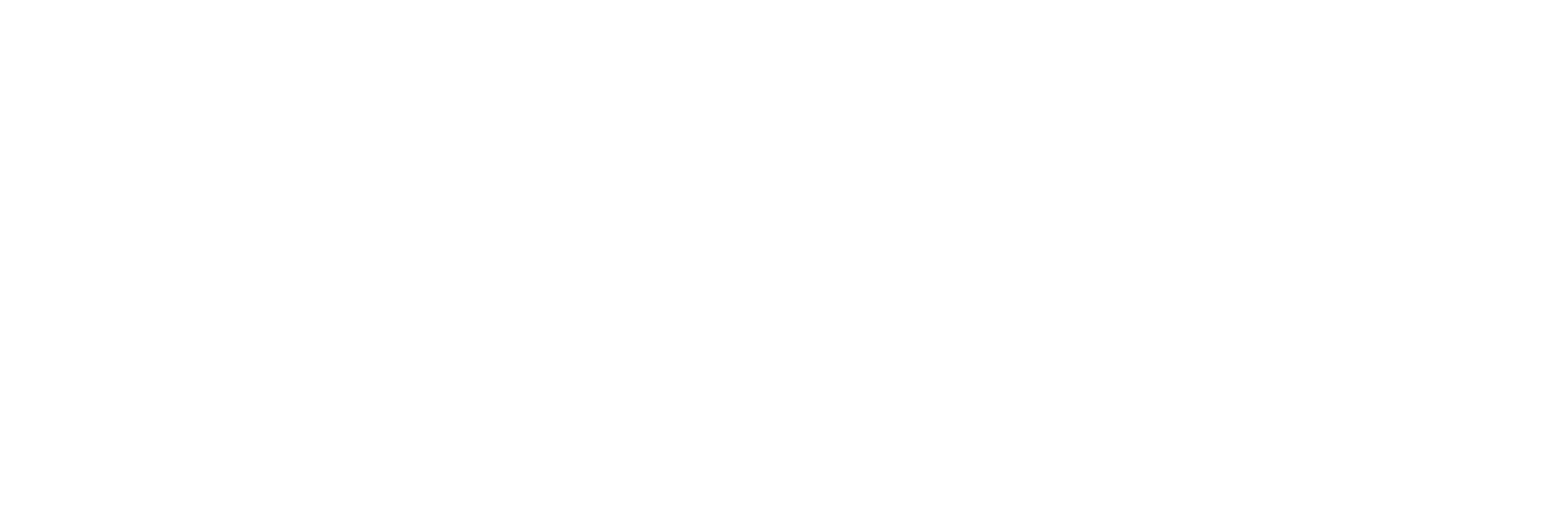

Funded by the German Agency for International Cooperation (GIZ), our team conducted a study on postharvest in selected value chains in Kenya. Within the results, some strategies stand out with great contributions to improve food and nutrition security through the reduction of postharvest losses, not well documented up to now. This is the case of the sweet potato value chain in Kenya, which provides nutritious food for humans and feed for livestock.

Figure 1. Sweet potato benefits, production locations, facts and consumption in Kenya. Click here for full image

Sweet potato value chain

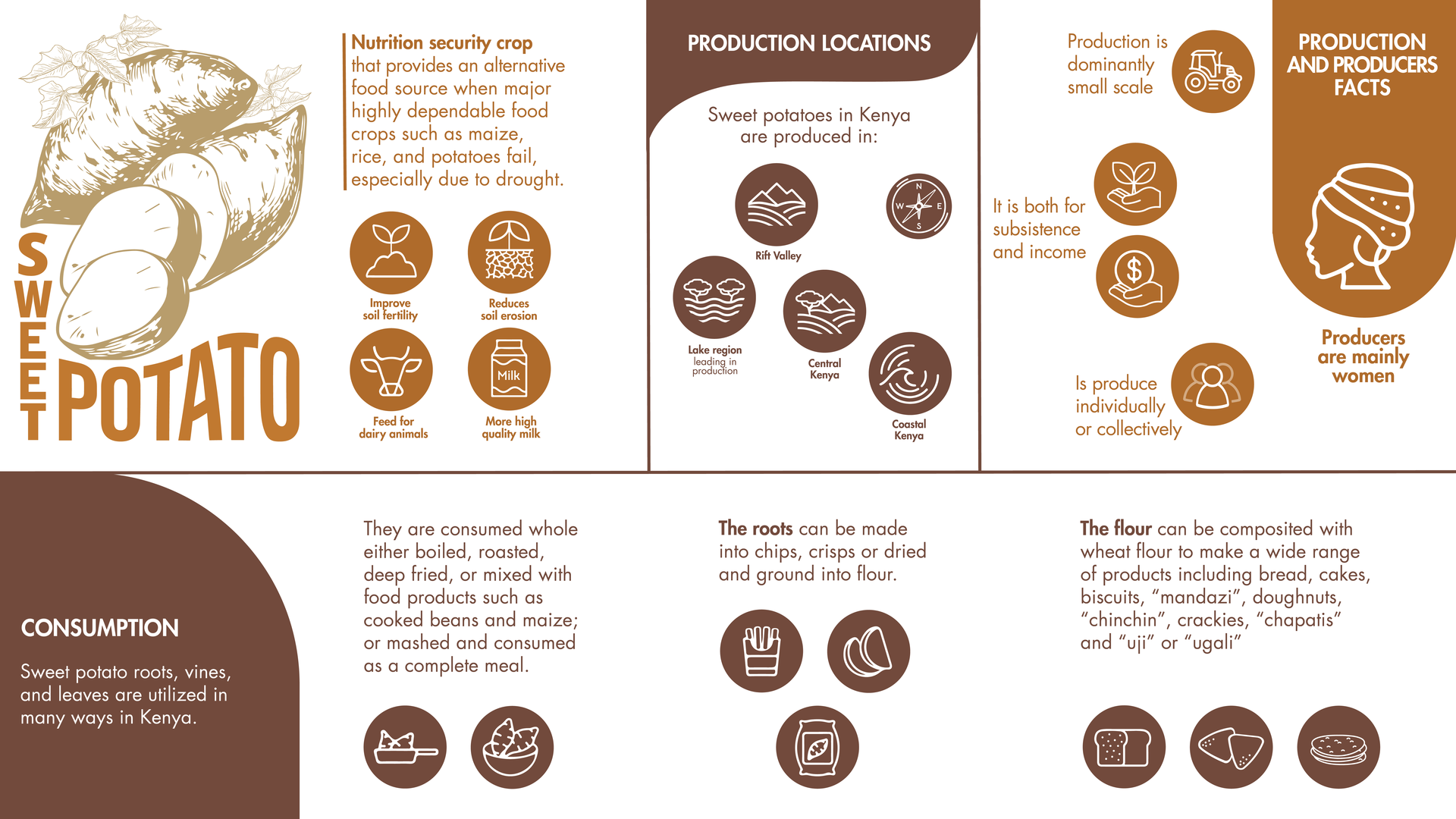

Figure 2 shows the Kenyan sweet potato value chain with its main characters, service delivery actors and external influences.

Figure 2. Sweet potato value chain map. Kenya. Adapted from Olwande et al, 2015 and other sources. Click here for the full image

The sweet potato value chain actors in Kenya experience several challenges causing postharvest losses. Lack of storage facilities experienced across the entire chain, for example, is a key contributor to postharvest losses since sweet potato is perishable and has a shelf life of a little more than a week. But the value chain also faces production and marketing constraints.

The major production constraints include: unfavorable weather conditions, since in cases of unpredictable rainfall the yield and the availability of sweet potato vines for planting are affected; lack of financial credit, since stringent conditions and requirements by formal institutions for accessing credit makes it difficult to access capital for investment; lack of advice on agronomic practices; high cost of inputs; and high incidences of pests and diseases, both of these can cause yield losses of up to 75 percent.

On the other hand, marketing constraints involve: low commodity prices and low demand occasioned by seasonal production leading to glut; unfavorable contractual agreements with buyers; high cost of transport; lack of proper standard packaging units resulting in exploitation by opportunistic behavior of brokers; unorganized spot markets where producers have low bargaining power; lack of standards for grading; fluctuation in supplies; poor roads; and lack of credit facilities.

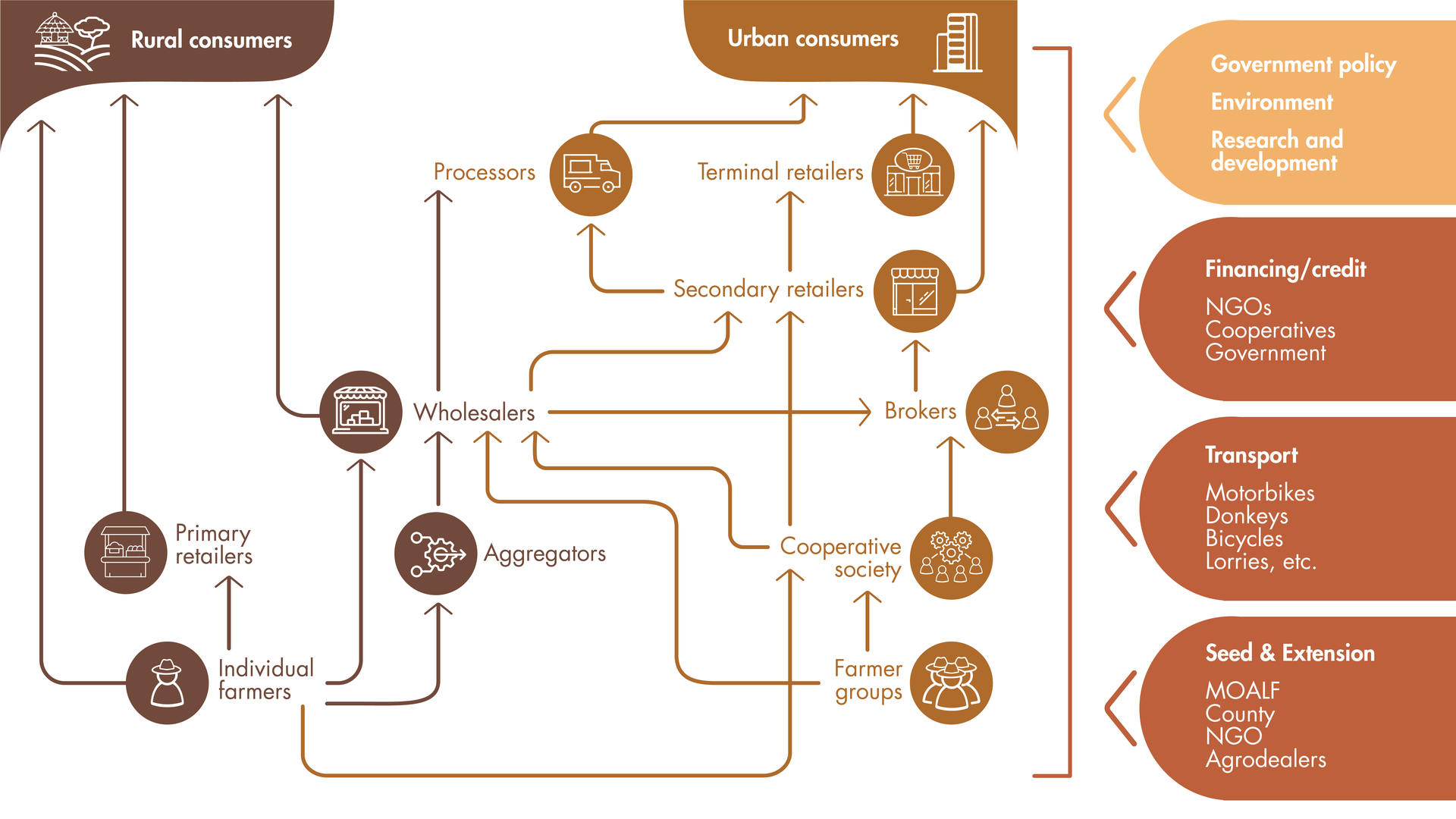

Post harvest losses in the sweet potato value chain

Postharvest losses occur cumulatively at different stages between harvest and final consumption, and the losses may be quantitative (physical loss of tubers through spillages and theft), qualitative (physiological degeneration including rotting and contamination) or both.

The following infographic shows the postharvest losses that occur on the farm, arranged according to three stages: during harvesting and handling; during transportation; and during storage.

Figure 3. Sweet potato postharvest losses. Kenya. Click here for the full image

Strategies for postharvest loss reduction in sweet potato value chain

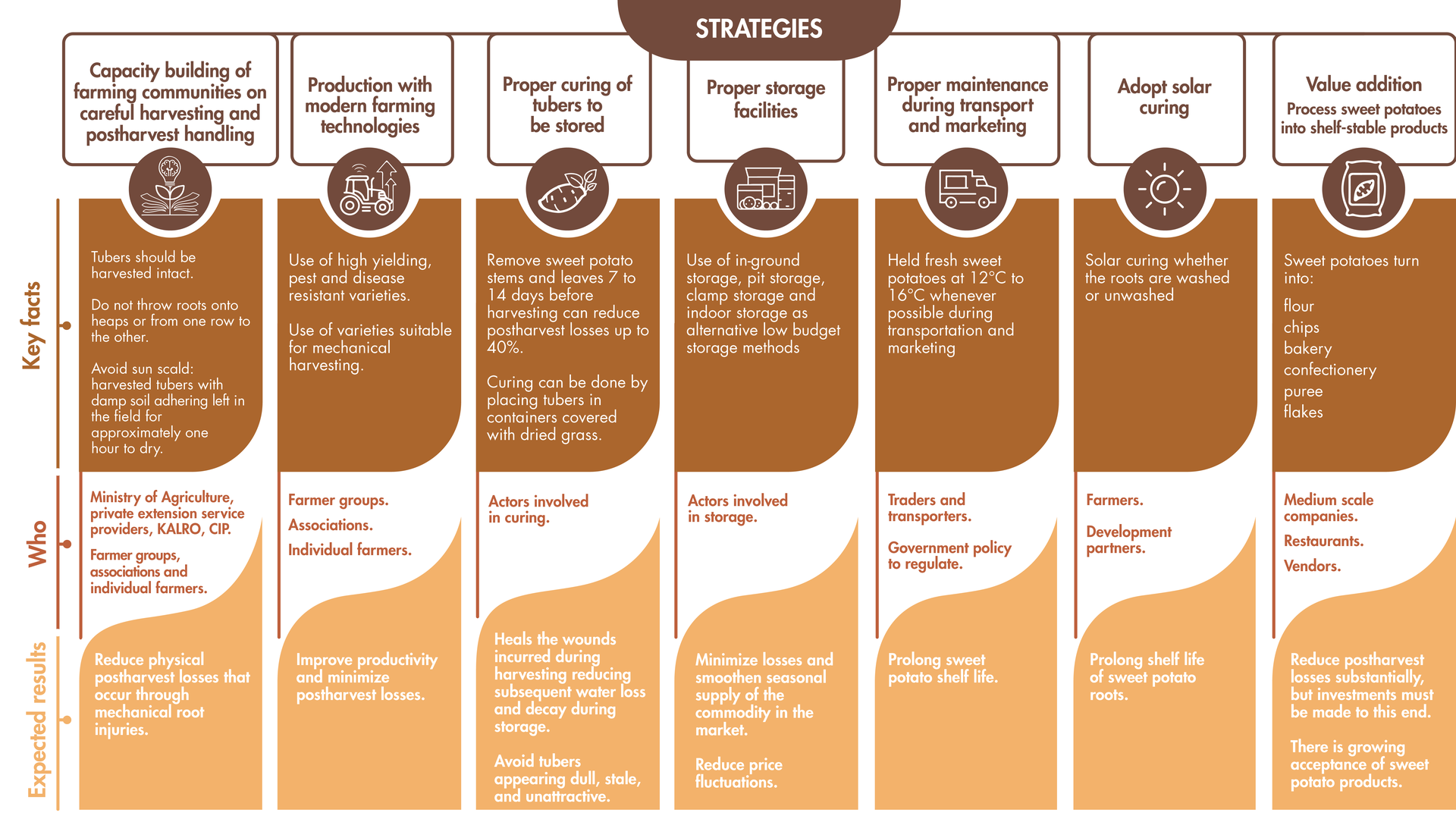

Once the dynamics of the value chain, its main production and marketing constraints, and the causes of postharvest losses at each stage were understood, our scientists proposed specific strategies to reduce these losses.

Figure 4 shows these strategies, along with the key facts that support them, the main actors involved and the expected results.

Figure 4. Strategies to reduce sweet potato postharvest losses. Kenya. Click here for the full image

As can be seen in the last column of the strategies, there is a special space reserved for value addition; a key component when it comes to transforming what is currently being discarded or lost into value, not only in terms of benefits for producers but also in terms of food and nutrition for consumers. In recent years, processing sweet potatoes into shelf-stable intermediate products such as flour, chips, and grits; baking them into chapati, mandazi, bread, scones, crackers, and doughnuts; slicing and drying them, or making sweet potato juices, vegetable relishes, and salads have been piloted in Kenya, and, at the same time, the opportunity to scale up these processing innovations has been shown. These value addition options have the potential to increase farmers income and present opportunities to reduce postharvest losses by increasing demand. Although currently done on a smaller scale targeting roadside vendors, school canteens, hotels, restaurants, and hospitals (Wayua et al, 2017), and on a medium scale by companies like Naivas and Organi limited, these newer value addition technologies when scaled up have the potential to improve nutrition and food security in the country, not only with the sweet potato value chain, but also with other farming commodities.

Related Publications

View the full set of infographics here